Is an innovative waste-to-energy facility in Western Australia the face of the future of waste management and energy generation in Australasia?

Entech’s low temperature gasification energy recovery process that converts solid waste into a synthetic gas is expected to provide enough energy to power 23,000 homes

New Energy Corporation Pty Ltd (New Energy) clearly thinks so, having invested heavily in processing a sizeable amount of the 54 million tonnes of garbage Australians create each year.

This massive total includes:

- 14.4 million tonnes of commercial and industrial waste – 44 percent of which ended up in landfill

- 3.9 billion plastic bags used in 2007 alone – 3.3. billion ending up in landfill.

New Energy aims to use an innovative, home-grown low temperature gasification technology to turn a significant proportion of Western Australia’s contribution to this waste mountain into energy.

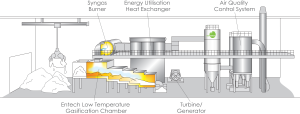

The Entech low temperature gasification energy recovery process converts solid waste into a synthetic gas which will provide enough energy to power 23,000 homes in the south west of the state each year.

The technology will be utilised at a 10ha site in East Rockingham near Perth that will house the AU$180 million New Energy Waste to Energy and Materials Recovery Facility (MRF), which is set to begin construction in October this year and is scheduled to be operational by the fourth quarter of 2017.

Consisting of four operational gasification chambers and one set aside for maintenance, the plant is expected to produce up to 18.5MW of electricity, of which 2.5MW would be used to power the plant and 16MW would feed into Western Australia’s South West Interconnected System.

The site is zoned for the environmentally acceptable heavy industry appropriate for this type of project, offering:

- Good site access for heavy vehicles

- Access to existing power infrastructure

- Synergies with existing industry in the area

- An acceptable distance from residential areas (about 2.5km)

- Correct zoning and alignment with future land use plans.

“We are incorporating front-end materials recovery processing ahead of energy recovery, demonstrating our technology satisfies the state’s stringent environmental regulations,” New Energy CEO Jason Pugh says.

“Our technologically advanced, on-site, front-end Materials Recovery Facility MRF will accept commercial and industrial, construction and demolition and municipal solid waste, inspect it and remove recyclables before using the remainder for energy recovery.”

The MRF will have the capacity to handle 225,000 tonnes of waste per year, which equates to 13 per cent of the waste that would otherwise be sent to landfill, turning 130,000 tonnes into energy after recyclables are removed.

Recyclable items such as concrete, bricks and metals will be recovered before the remaining municipal solid waste, plastic bags and wrapping, contaminated cardboard and timber packaging from construction and demolition projects is sent to generate energy instead of going to landfill.

Entech’s unique gasification technology sees the waste slowly ‘cooked’ over 16 to 24 hours, reaching temperatures between 600°C and 875°C during which small quantities of air and steam are introduced.

This breaks up the molecules in the waste, which are converted into a synthetic gas or ‘syngas’ that is transferred to a burner to heat water-producing steam used directly for heating, industry processes or to generate electricity for the grid.

This two-stage approach means the carbon is thoroughly removed and combusted, releasing the maximum energy from the waste and delivering superior environmental performance for organic pollutants like dioxins and PAHs.

The new generation energy recovery system offers numerous environmentally friendly advantages:

- The syngas is fired to generate heat and this secondary oxidation stage converts the syngas to carbon dioxide and water vapour, which is then cleaned and filtered to neutralise acidic gases like sulphur dioxide and to remove any trace particulates and heavy metals before the carbon dioxide and water vapour is safely released to the atmosphere

- The plant will only process Class I, II and II waste and not hazardous wastes using an extremely flexible gasification system that has been proven on many waste streams

- All waste will be handled inside an enclosed, ventilated building, preventing the escape of odours, while ventilation air will be treated in the energy recovery process to destroy odour

- All operations occur indoors, the materials recovery facility and energy recovery processes are relatively quiet and the power generation equipment is housed in special acoustic enclosures to reduce noise

- The process keeps dust to a minimum as major plant activities occur indoors where the dust is contained, the waste is handled in bulk for inspection and recyclables removal

- The only stream emitted to air is from the stack and consists of carbon dioxide and water vapour with trace amounts of other compounds which meet the stringent European Union Air emissions standards that have been adopted in WA. Stack emissions are tested continuously and displayed in real time in the plant control room as an additional safeguard

- The small volumes of ash, lime and activated carbon that are generated in the energy recovery process are inert and stable and suitable for disposal in landfill as it is similar to the ash from a slow combustion stove and has no energy content.

The Rockingham project will:

- Divert approximately 150,000 tonnes of waste from landfill

- Create energy to power 23,000 homes

- Target waste left over from recycling and recovery operations

- See up to 80 percent of energy produced deemed renewable

- Australian-first waste management infrastructure

- Support waste management for large industrial projects

- Create approximately 30 full-time jobs

- And be environmentally sustainable.

Established in 2009, New Energy is the global licensee (ex Americas) for the Entech low temperature gasification energy recovery process that was originally developed in West Australia and has been successfully deployed in Europe and Asia.

The Rockingham plant is the second of New Energy’s waste-to-energy projects to receive approval from the West Australian Environmental Protection Authority following the Boodarie Industrial Estate installation at Port Hedland in the north of the state, which was greenlit two years ago to provide electricity for 21,000 homes and export 15.5MW to the grid.

The Hedland plant approval made New Energy the first Australian company to have a waste-to-energy project of this kind approved by a government environmental protection authority, providing a major boost to the company’s vision of a world with zero landfill where waste fuels a sustainable future.